Siedery offers precision CNC machining services including CNC turning, CNC milling, EDM, wire EDM and surface grinding. Combined With our precision 3-, 4- and 5-axis CNC machining centers, and our extensive experience in servicing multinational projects, we can machine all types of parts in all metals and plastic materials. Whether you require small batches prototypes or high-volume production parts, we will be your best option. We are positioned to serve small and medium-sized enterprises worldwide and guarantee to manufacture parts from quotation to machining in a few days!

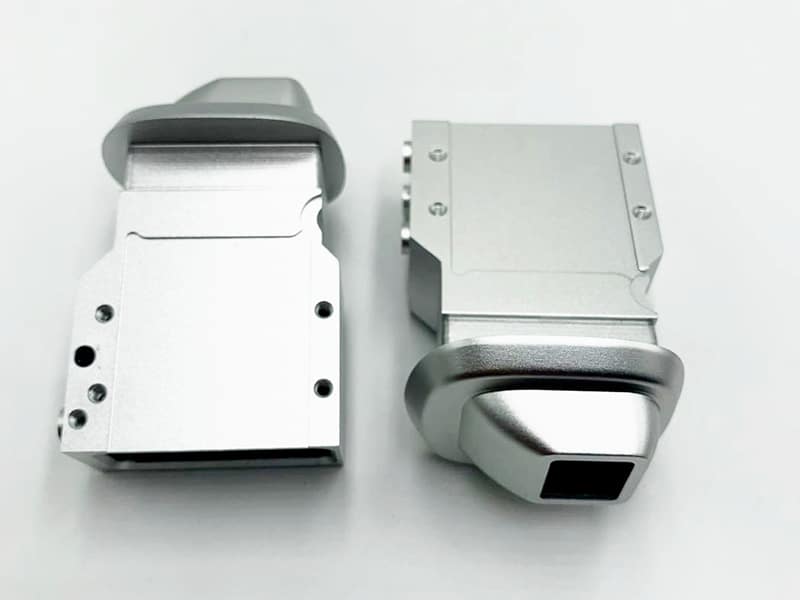

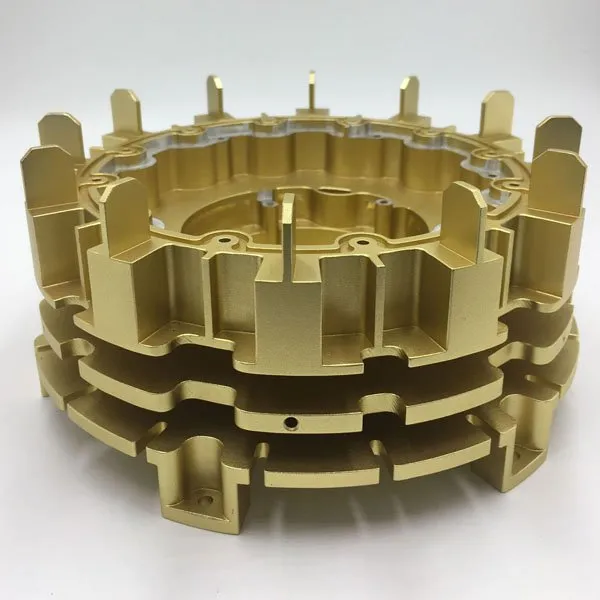

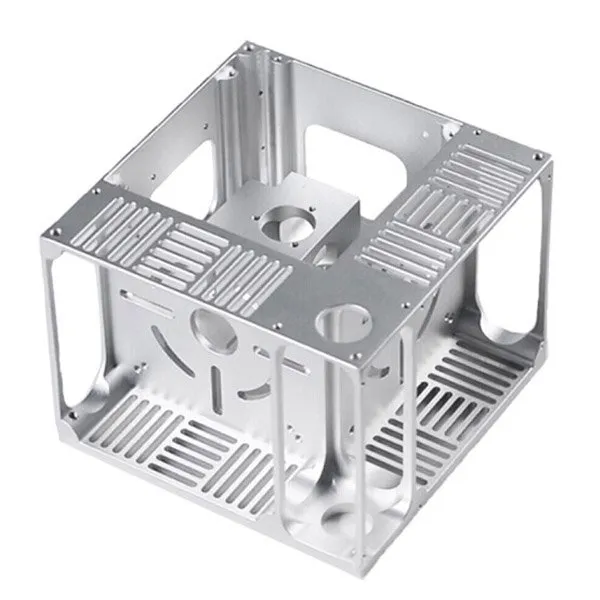

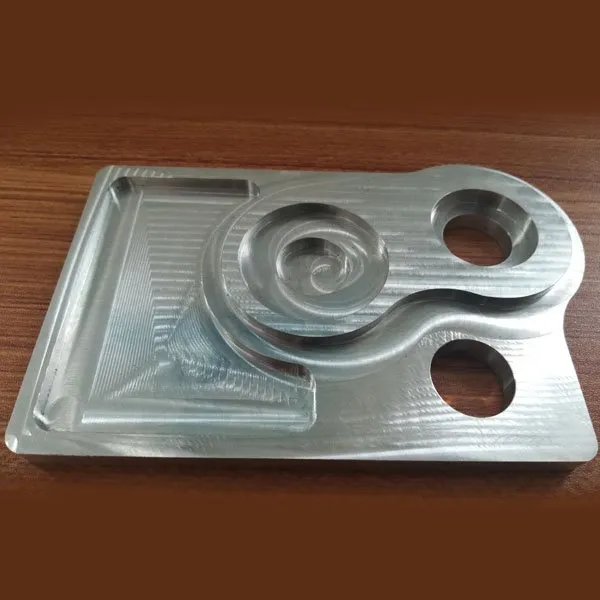

CNC milling is a machining process that uses computer-controlled and rotating multi-point cutting tools to progressively remove material from a workpiece to produce a custom-designed part or product. The process is suitable for machining a variety of materials such as metals and plastics. CNC milling, particularly 5-axis milling, can be used to create complex 3D shapes, allowing the creation of many different types of complex geometric part features including holes, curves, slots, mitred shapes and channels. Milling is also ideal method for creating pressure castings and plastic injection molds.

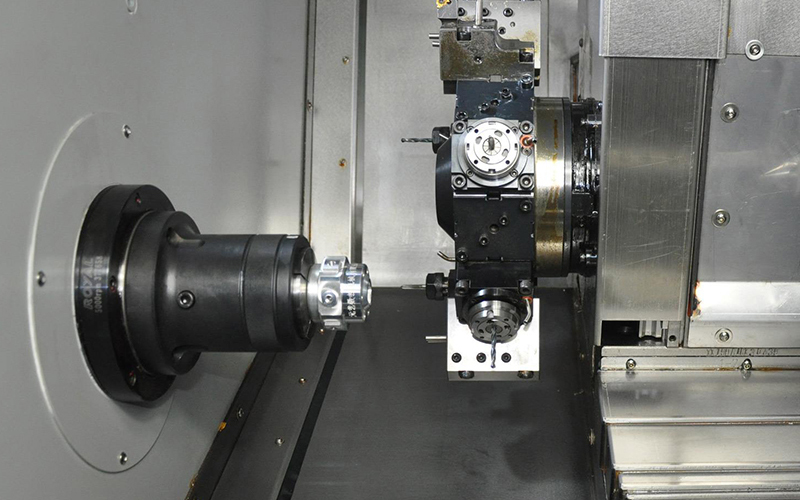

CNC turning is one of the widely used CNC machines. It is mainly used for cutting internal and external cylindrical surfaces of shaft parts or disc parts, internal and external conical surfaces of any taper angle, complex rotating internal and external surfaces as well as cylindrical and conical threads. It can also be slot,ream and bore holes. CNC turning is a more efficient method than CNC milling, and Siedery's turning capabilities can cover parts from prototype to mass production.

Why would you need to choose us from a large number of CNC machining service providers? Here are the top 4 reasons.

1. Experience

Our project managers and engineers have extensive experience in multinational services, so they are able to solve problems encountered during the project advancement process and smoothly handle complex and precise parts for multiple industries.

2. Advanced equipment

Siedery has an extensive range of in-house equipment for manufacturing and testing. Your parts will be manufactured and tested on our state-of-the-art equipment including 3-, 4- and 5-axis CNC milling machines and advanced measurement system.

3. Cost saving

With efficient management, strong component machining capabilities and strict cost control, we are always able to offer lower price for the same level of component machining.

4. Fast delivery

We quote you within 24 hours on average and parts are shipped in 5 days or less, we can do it!

Before you consider using CNC machining to manufacture your parts, you must know what kind of materials and surface treatments to apply to your CNC machined parts. Siedery is not only a processing factory, but also has excellent surface treatment and finishing partners which can complete various types of finishing for prototype parts and production parts. Need to customize CNC parts with high-quality appearance? Siedery provides you with the best service.

Plastic: ABS,Acetal,CPVC,Delrin (POM),HDPE,LDPE,Nylon,PEEK,PEI,PET,PMMA,Polycarbonate,Polypropylene ,PPSU,PS,PSU,PTFE,PVC,Acrylic,Delrin,PPS,UHMW,Ultem

Metal:Aluminum,Brass,Copper,Stainless Steel,Steel Alloy,Steel Mild Low Carbon,Titanium,Bronze,Cast Iron.Learn more about CNC metal materials...

For more plastic materials to be processed, please contact our team.

Anodizing gives high corrosion resistance, high hardness, high adsorption capacity, very good insulating properties, and very high heat resistance.

The powder spraying process uses automatic reciprocating spraying coupled with manual replenishment spraying to avoid missing spraying on dead corners of the workpiece, to enhance the uniformity of the spraying thickness and to improve the anti-corrosion performance of the product.

Electroplating is the process of using electrolysis to coat the surface of certain metals with a thin layer of other metals or alloys. It is a process of using electrolysis to attach a metal film to the surface of metals or other materials to prevent corrosion, improve wear resistance, electrical conductivity, reflectivity and aesthetics.

Polishing is a processing method that uses mechanical, chemical or electrochemical action to reduce the surface roughness of a workpiece in order to obtain a bright, flat surface. It is a finishing process on the surface of the workpiece using polishing tools and abrasive particles or other polishing media.

The main purpose of brushing is to remove oxidation, rust marks and machined burrs from the surface of the part, to produce a regular, fine fillet pattern on the surface of the part or to obtain a wrought surface appearance without light. Brushing does not change the geometry of the part. Commonly used brush wheels are generally made of steel wire, brass wire and other materials, sometimes other materials are used for special purposes.

The process of cleaning and roughening the surface of the substrate by using the impact of the high speed sand flow, so that the surface of the part obtains a certain degree of cleanliness and different roughness, so that the mechanical properties of the surface of the workpiece are improved, therefore increasing the fatigue resistance of the workpiece, increasing the adhesion between it and the coating, extending the durability of the coating film and also facilitating the leveling and decoration of the coating.

CNC is an automated machine tool equipped with a programmed control system, also known as a CNC machine tool or CNC lathe. It is mainly used for large-scale machining of parts in the form of external turning, boring, turning of surfaces, etc. It can be programmed and is suitable for mass production, with a high degree of automation in the production process. CNC machines are widely used in the manufacturing industry, especially in the automotive, aerospace and military industries.

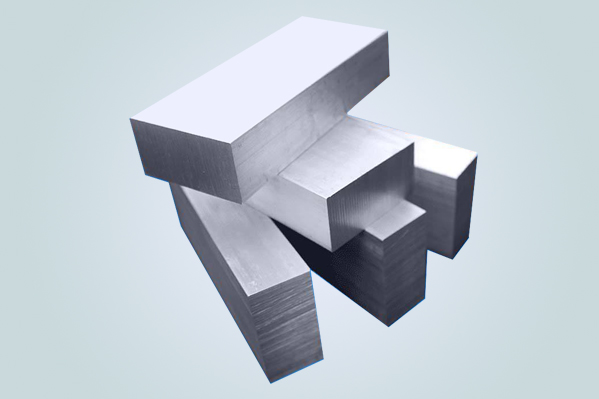

CNC, or computer numerical control machining, is a subtractive manufacturing method that leverages a combination of computerized controls and machine tools to remove layers from a solid block of material. The desired cuts in the metal are programmed according to corresponding tools and machinery, which perform the machining task in an automated fashion.

According to the technical requirements of the parts processing and process requirements, write the processing program of the parts, and then input the processing program to the numerical control device, and the numerical control device would control the machine tool spindle movement, feed movement, tool replacement, as well as the clamping and unclamping of the workpiece, cooling, lubrication pump on and off, so that the tool, workpiece and other auxiliary devices would be in strict accordance with the sequence, trajectory and parameters specified in the processing program, thus producing parts that meet the requirements of the drawings.

CNC machining is available for a wide range of materials, most commonly aluminium, steel, brass, ABS and nylon. In practice, however, CNC machining can be carried out on almost any hard material.

3D printing is an additive technology and CNC machining is a subtractive technology, so they are very different in terms of materials.

The main materials used in 3D printing are liquid resin (SLA), nylon powder (SLS), metal powder (SLM), gypsum powder (full colour printing), sandstone powder (full colour printing), wire (FDM), sheet (LOM) and so on. Liquid resins, nylon powders and metal powders make up the vast majority of the market for industrial 3D printing.

The materials used for CNC machining are all piece by piece, that is, sheet materials, which are measured by measuring the length, width, height + wear and tear of the part and then going to cut the corresponding size of the sheet for machining.

Compared to parts manufactured by additive methods (3D printing), CNC machined parts are functionally stronger and usually have a higher production quality and surface finish. For this reason, CNC machining is usually used in the mid to late stages of development, when parts are ready for testing, functional accuracy, high volume production.

Depending on the type of part to be machined, there are different types of CNC machines best suited to the job. CNC milling utilizes a CNC milling machine which consists of a multi-axis system (three, four or five axes, depending on the complexity of the part). CNC turning involves a lathe, usually with two axes, which uses circular motion to cut the workpiece. Electric discharge machining machines (EDM) uses electric sparks to shape the workpiece into the desired shape. Hobbing is another machining process and is used to cut gears, splines and sprockets. Other CNC machine types include plasma cutting machines and water jet cutting machines.

CNC design, with only a few words, actually contains the mastery of CNC machine tools and lathe processing technology, mastering this point will master most of the content of machining. It is recommended that before designing the process of CNC lathe, you should know the whole processing process well, you can go to the workshop in advance to see more, do not easily write down, and wait until you have a number of things in mind before you can finish it in one go, otherwise the process design will cause a laughing stock. It is not surprising that the initial design stage will encounter similar problems, but as long as you think hard, read more and learn more, you will quickly master it.

As technology continues to develop, there is an increasing demand for precision machining in the industrial manufacturing industry, so CNC machining is widely off the main. What is the difference between CNC machining and traditional machining, Siedery shares with you from the following five aspects.

In short, on the basis of traditional machining processes, CNC machining technology has become the main development direction of the modern machining industry. It not only continues the current processing methods of CNC lathes as well as ordinary lathes, but also effectively absorbs the mature technology and processing methods of the traditional machining process.

Founded in 2011, Siedery provides a one-stop shop for additive manufacturing and small-batch manufacturing services for small and medium-sized enterprises worldwide. We are experts in the CNC machining, injection molding, and 3D printing industries.